Vertical Loads

In applications where there is a constant torque![]() Torque is the tendency of a force to rotate an object about an axis. Just as a force is a push or a pull, a torque can be thought of as a twist being applied to the motor shaft (ie: gravity pulling a vertical load) special considerations need to be made to make sure the load doesn’t move excessively before the brake is applied.

Torque is the tendency of a force to rotate an object about an axis. Just as a force is a push or a pull, a torque can be thought of as a twist being applied to the motor shaft (ie: gravity pulling a vertical load) special considerations need to be made to make sure the load doesn’t move excessively before the brake is applied.

Disable modes

It is generally recommended to use AXIS#.DISMODE 2 or 3 to have the drive stop the motor and hold it in position until the brake has been applied. This provides the most control over the shaft while disabling and ensures the motor is stopped before applying the brake.

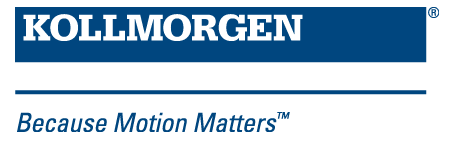

The chart below shows the drive behavior for DISMODE 2 and 3 with AXIS#.CS.DEC of 10,000 rpm/s, AXIS#.CS.VTHRESH = 100 rpm, and AXIS#.MOTOR.TBRAKEAPP = 15 ms.

AXIS#.DISMODE = 2 or 3 (controlled stop)

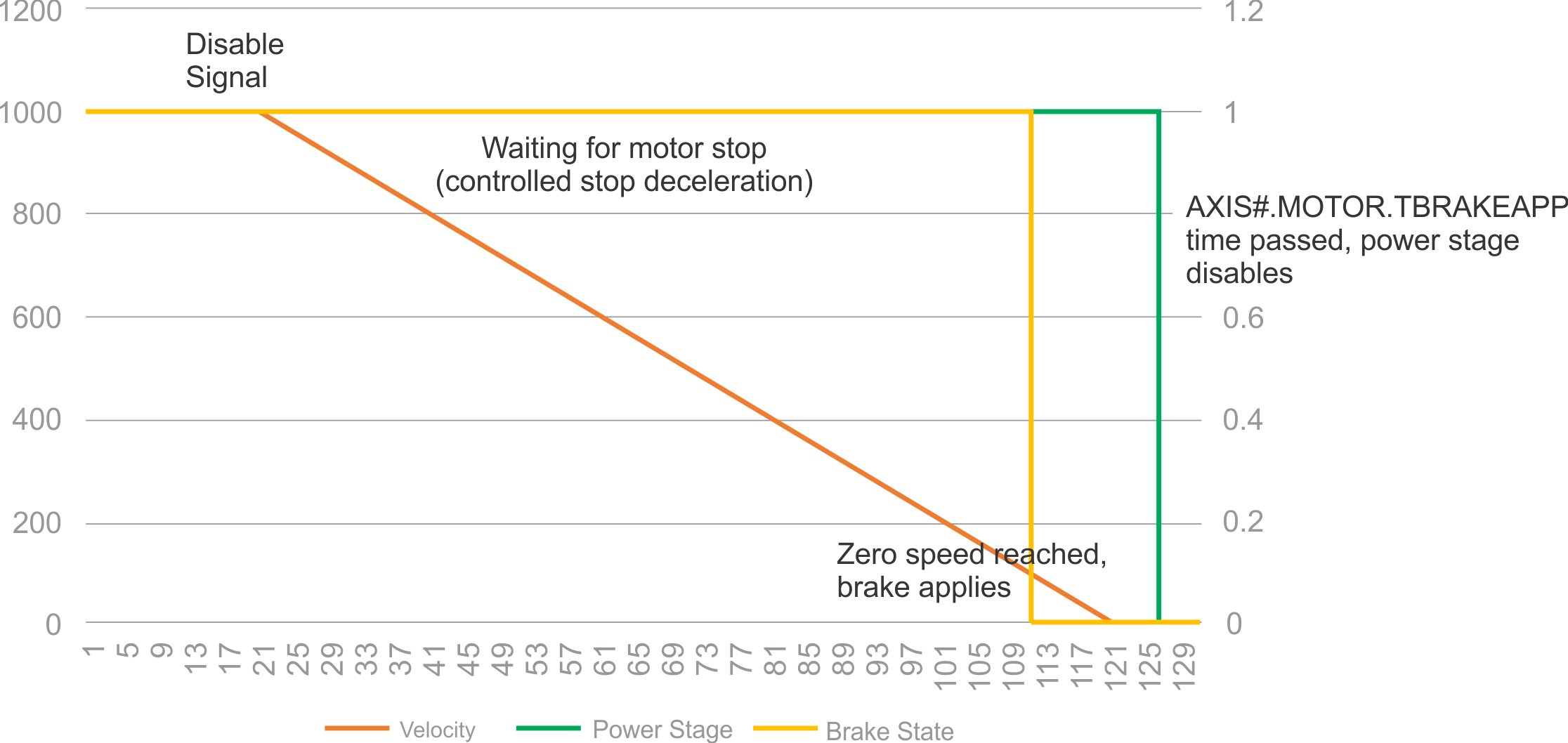

Disable mode 0 (disable immediately) will disable the power stage and use friction to coast to a stop. If a constant torque is being applied, the axis may not reach the AXIS#.CS.VTHRESH threshold required to apply the brake and the load will drop until it hits something. This can be alleviated somewhat by using AXIS#.MOTOR.BRAKEIMM or AXIS#.MOTOR.TBRAKETO, but the load will still move before the brake is able to be applied and the brake will be applied to a moving motor shaft consistently, which is undesirable and lead to premature hardware failure.

AXIS#.DISMODE = 0 (disable power stage immediately)

Disable mode 1 (dynamic brake) will use dynamic brake to stop the motor. While better than mode 0, this mode may still result in some shaft movement before the brake can be applied due to the nature of dynamic brake. There will be a minimum speed that the shaft will rotate while dynamic braking. Similar to mode 0, if AXIS#.CS.VTHRESH is below the speed at which the load drops, the brake will not apply unless AXIS#.MOTOR.BRAKEIMM or AXIS#.MOTOR.TBRAKETO are configured.

AXIS#.MOTOR.BRAKEIMM Configuration

The AXIS#.MOTOR.BRAKEIMM parameter should be set to 1 in vertical load applications. It specifies whether the drive should apply the brake when the power stage disables regardless of whether the axis has reached AXIS#.DISVTHRESH threshold. AXIS#.MOTOR.BRAKEIMM has no effect while disabling with a controlled stop under normal conditions. The drive will follow the AXIS#.CS.DEC rate until it reaches AXIS#.DISVTHRESH threshold and apply the brake regardless of the AXIS#.MOTOR.BRAKEIMM setting. If a fault occurs such that a controlled stop cannot be followed, the drive will disable the power stage immediately causing the axis to use friction to come to a stop. In vertical load applications with a constant torque on the motor, letting the axis coast is dangerous. The BRAKEIMM parameter will make sure the brake applies as soon as the drive detects the fault condition regardless of the velocity.

-

- While the brake will apply as fast as possible after disabling the power stage, the load may still drop some and the brake will be used on a moving shaft.

AXIS#.MOTOR.TBRAKETO Configuration

AXIS#.MOTOR.TBRAKETO applies the brake after a certain time has passed without reaching AXIS#.CS.VTHRESH threshold. This is useful to make sure that the brake applies in the event the load moves faster than the defined threshold. It should be thought of as a back-up setting and it should not hit this timeout under normal circumstances. As previously mentioned, stopping the shaft with the brake while in motion will lead to premature hardware failure.